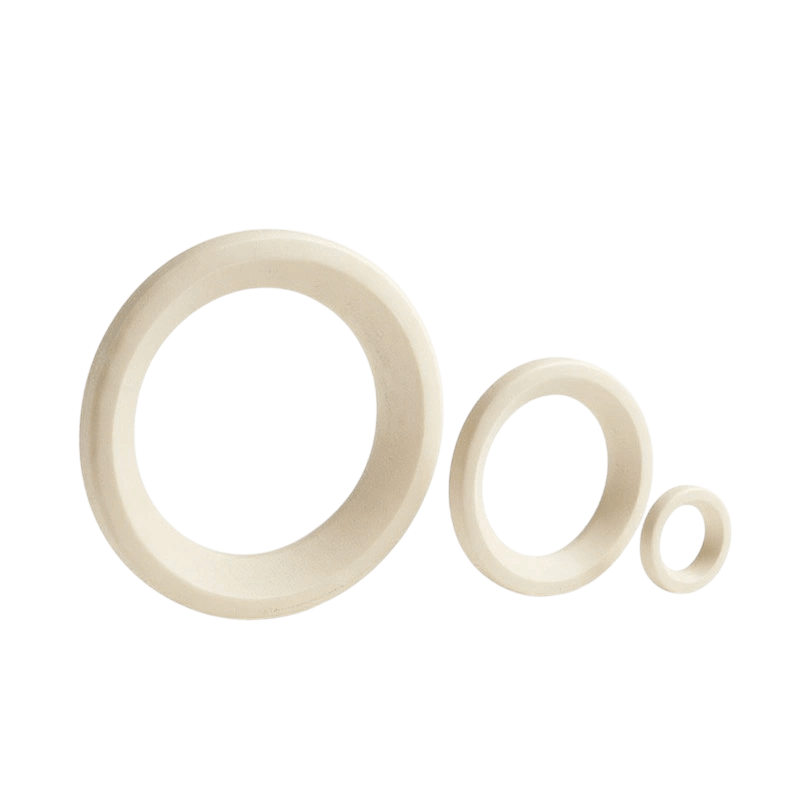

25% Glass-Filled PTFE Gasket

واشر پر شده با ۲۵٪ شیشهتماس با ما: 88175113

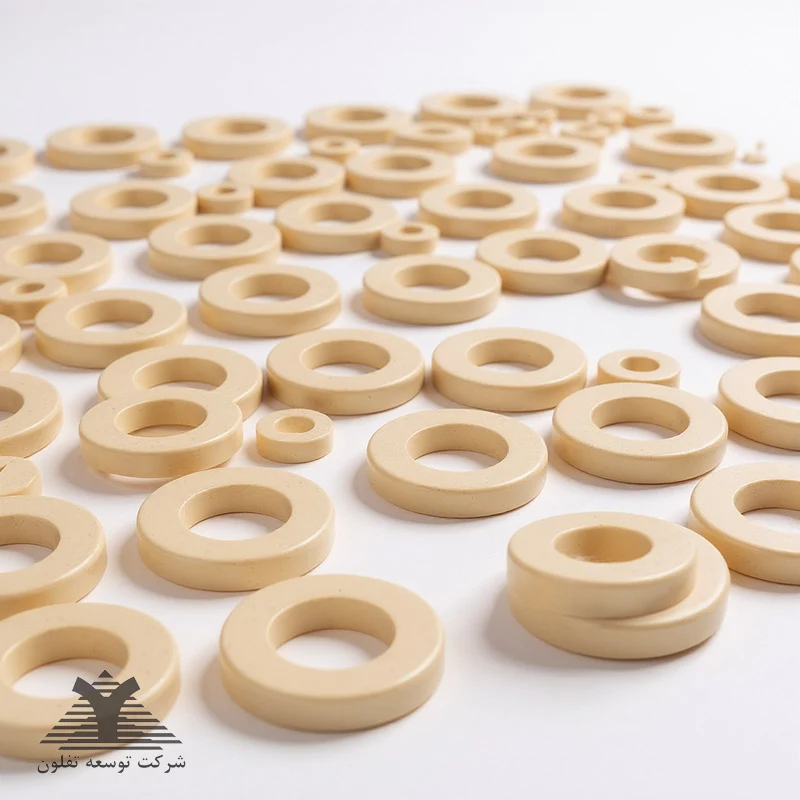

برای استعلام قیمت واشر پر شده با 25% شیشه و ثبت سفارش، ابعاد فلنج، نوع سیال، دما و فشار کاری را برای ما ارسال کنید. تیم فنی توسعه تفلون با توجه به شرایط کاری شما، مناسبترین سایز و ضخامت این واشر PTFE را پیشنهاد میدهد و امکان تولید در ابعاد استاندارد و سفارشی فراهم است.

25% Glass-Filled PTFE Gasket | A Smart Balance of Chemical Resistance and Mechanical Strength

25% Glass-Filled PTFE is a reinforced grade of PTFE designed for applications where chemical resistance alone is not sufficient and higher mechanical strength is required.

The glass fibers embedded within the PTFE matrix significantly improve dimensional stability and reduce creep under load. This glass-filled PTFE gasket maintains its shape across a wide temperature range and is a reliable choice for flanges subjected to continuous mechanical stress.

In chemical and petrochemical process lines—where leakage or gasket deformation is unacceptable—this grade provides an optimal balance between mechanical durability and chemical resistance.

To request pricing for 25% Glass-Filled PTFE gaskets and determine the proper size, our engineering team can advise you based on your process fluid, operating pressure, and temperature.

The 25% Glass-Filled PTFE grade is selected when you still require chemical behavior similar to virgin PTFE but need a gasket that will not deform under sustained load.

The addition of glass fibers increases rigidity, enhances dimensional stability, and significantly reduces creep. For this reason, glass-filled PTFE is highly effective in flanges that remain tightened for long periods without frequent disassembly.

In applications where the environment is chemically active but not extremely aggressive, this material offers an excellent balance of good chemical resistance and improved mechanical strength.

For process lines where downtime is costly, choosing the correct thickness and grade can substantially extend service life, reducing replacement frequency and making the long-term cost of glass-filled PTFE highly economical

Key Technical Specifications of 25% Glass-Filled PTFE Gaskets

- The base material is PTFE reinforced with approximately 25% glass fibers.

- This grade provides superior dimensional stability and higher mechanical strength under load compared to virgin PTFE.

- It offers improved resistance to creep and long-term deformation under continuous mechanical stress.

- Its typical operating temperature range is approximately –200°C to +260°C.

- It maintains strong chemical resistance against most acids, alkalis, and common industrial process fluids.

- It is a more reliable choice than virgin PTFE for flanges and static joints subjected to long-term, sustained loading.

- Its wear resistance is significantly higher than that of standard PTFE gaskets.

- The gasket surface remains relatively non-stick and smooth, allowing for easy cleaning.

- It can be machined and cut into both standard and fully customized dimensions.

- For applications requiring a balanced combination of mechanical strength and chemical resistance, this grade provides a highly reliable and cost-effective solution.

Advantages and Limitations of 25% Glass-Filled PTFE — When Is This Grade the Smart Choice?

Twenty-five percent glass-filled PTFE sits between virgin PTFE and metal-filled grades—offering greater rigidity and load resistance than pure PTFE, without the aggressive hardness of bronze- or carbon-filled formulations. Understanding its advantages and limitations helps determine where this material excels and where an alternative grade may be more appropriate.

When 25% Glass-Filled PTFE Provides the Ideal Balance

When 25% Glass-Filled PTFE Is Not the Ideal Choice

25% Glass-Filled PTFE Compared to Other PTFE Gasket Grades — Technical Comparison Table

Before finalizing the selection of a 25% glass-filled PTFE gasket or any alternative PTFE grade, it is important to understand the role each formulation is designed to serve.

The comparison table below outlines how 25% glass-filled PTFE performs relative to carbon-filled, bronze-filled, and advanced composite grades—helping you determine which option offers the most appropriate balance of technical performance and cost for your application.

| PTFE Gasket Grade | Primary Design Focus | Performance Under Long-Term Static Load | Behavior in Dynamic Motion & Wear | Suitability for Sanitary / Hygienic Environments | Approximate Cost Level | Recommended Application Scenario |

|---|---|---|---|---|---|---|

| Virgin PTFE | Maximum chemical resistance and purity | Good performance under moderate pressure; less stable at very high loads | Not suitable for severe dynamic wear or motion | Excellent for food, beverage, and pharmaceutical environments | Medium to high cost | referred when fluid aggressiveness is very high and purity/hygiene are critical priorities. |

| 25% Glass-Filled PTFE | Balanced chemical resistance and mechanical stiffness | Good dimensional stability under sustained static load | Acceptable performance under moderate wear | Suitable for many clean industrial environments | Medium cost | Ideal when long-term stability matters and you want reliable performance without moving to higher-cost composite grades. |

| Carbon-Filled PTFE | Enhanced strength and stiffness under load | Higher pressure capability than virgin or glass-filled PTFE | Better suited for increased wear and moderate dynamic motion | Suitable for some hygienic environments depending on standards | Medium to high cost | Recommended when higher pressure and some wear are present while chemical resistance remains important. |

| 40% Bronze-Filled PTFE | High mechanical load capacity and improved thermal conductivity | Very stable under high-pressure flange conditions | Strong performance in semi-dynamic wear scenarios | Less suitable for sensitive hygienic environments | High cost | Used in hydraulic systems, petrochemical service, and equipment exposed to both high pressure and temperature. |

| Bronze–Molybdenum PTFE (MoS₂) | Designed for extreme pressure and severe wear | Very low creep at high loads | Excellent for dynamic motion and high vibration | Typically used in heavy industrial service, not ultra-hygienic lines | High cost | Preferred when downtime is costly and maximum gasket life is required. |

| Carbon-Fiber + MoS₂ PTFE | Engineered for severe wear and combined high-load conditions | Highly stable under high pressure and cyclic loading | One of the best options for continuous motion and persistent abrasion | Used primarily in specialized industrial applications | Very high cost | Recommended for high-pressure systems, rotating equipment, and very demanding service requiring advanced composite performance. |

Where to Use 25% Glass-Filled PTFE — Real Industrial Process Applications

A 25% glass-filled PTFE gasket is selected when the process line is static, exposed to continuous pressure, and contains chemical media—where long-term deformation of the gasket is unacceptable.

In such conditions, the improved dimensional stability of glass-filled PTFE provides a practical middle ground between virgin PTFE and more rigid metal-filled grades.

For flanges and critical joints, the following applications are where this material typically delivers its best performance.

Paints, Resins, and Organic Solvents

Suitable for process lines handling solvents, resins, and coating materials where both chemical resistance and mechanical durability are required.

Chemical Storage Tanks and Reactors

Used on tank-top flanges and reactor connections subjected to sustained, long-term loading.

Detergent, Cosmetic, and Industrial Hygiene Formulations

Ideal for joints exposed to detergents and semi-sanitary formulations where gasket deformation must be minimized.

Industrial Water and Wastewater Treatment

Effective for flanges and joints exposed to mildly to moderately corrosive media where long-term sealing stability is essential.

Chemical Process Lines with Constant Pressure

Suitable for permanently tightened flanges carrying chemical media under steady operating pressure.

Heat Exchangers and Medium-Temperature Lines

Used in connections where temperature stability matters and long-term creep could otherwise lead to leakage.

Frequently Asked Questions About 25% Glass-Filled PTFE Gaskets

Glass-filled PTFE is engineered for applications where virgin PTFE gradually creeps under continuous static load, eventually leading to flange relaxation and minor leakage. The added glass fibers increase stiffness and dimensional stability, significantly reducing creep.

For flanges that remain tightened for long periods without frequent disassembly, 25% glass-filled PTFE provides a more reliable and long-lasting seal than softer PTFE formulations.

This grade is recommended when the process fluid is corrosive but not in the most aggressive chemical category, and the flange assembly is subjected to continuous pressure and meaningful bolt load. In these cases, you still need strong chemical resistance, but also require a gasket that will not deform or creep over time.

For ultra-sanitary systems or highly aggressive chemical environments, virgin PTFE remains the safer and more appropriate choice.

This material is intended primarily for static or semi-static joints under continuous load, not for extreme dynamic conditions. While it offers better wear resistance than virgin PTFE, glass-filled PTFE is not the best choice for continuous motion, intense vibration, or severe abrasion.

For demanding dynamic environments, bronze-filled PTFE, bronze–MoS₂ composites, or carbon-fiber–MoS₂ grades typically deliver superior performance. Always consider the type and intensity of motion when evaluating this material for your application.

In terms of cost, 25% glass-filled PTFE typically falls in the mid-range—more expensive than standard PTFE gaskets, yet more economical than advanced composite grades such as carbon-fiber + MoS₂.

However, in many chemical and process applications, its extended service life under continuous static load often offsets the initial purchase cost by reducing flange retightening, downtime, and gasket replacement frequency.

For applications where creep, gradual leakage, and unplanned shutdowns are costly, this grade frequently becomes the most cost-effective technical choice.