Industrial PTFE gaskets – manufactured and supplied to match your exact requirements

PTFE Teflon gaskets with high chemical resistance, low friction and excellent thermal stability provide a reliable sealing solution for flanges, fittings and process lines in the oil & gas, chemical, food and pharmaceutical industries. At ToseeTeflon, we offer production in both standard and fully customised dimensions to meet the exact specifications of your project.

Request a gasket consultation & supply quote

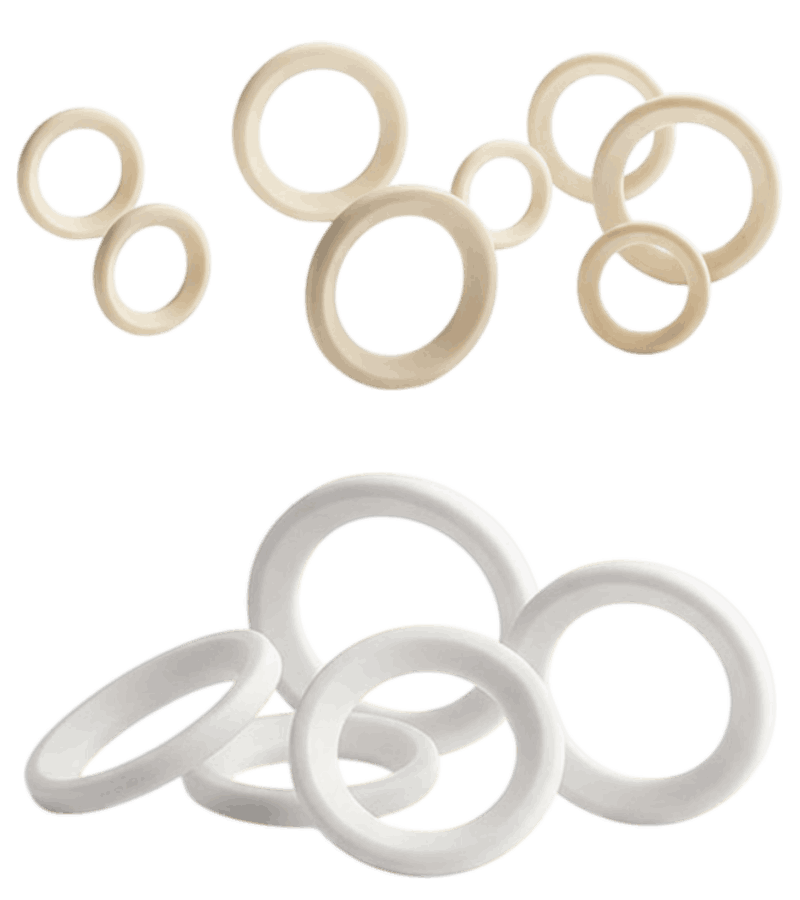

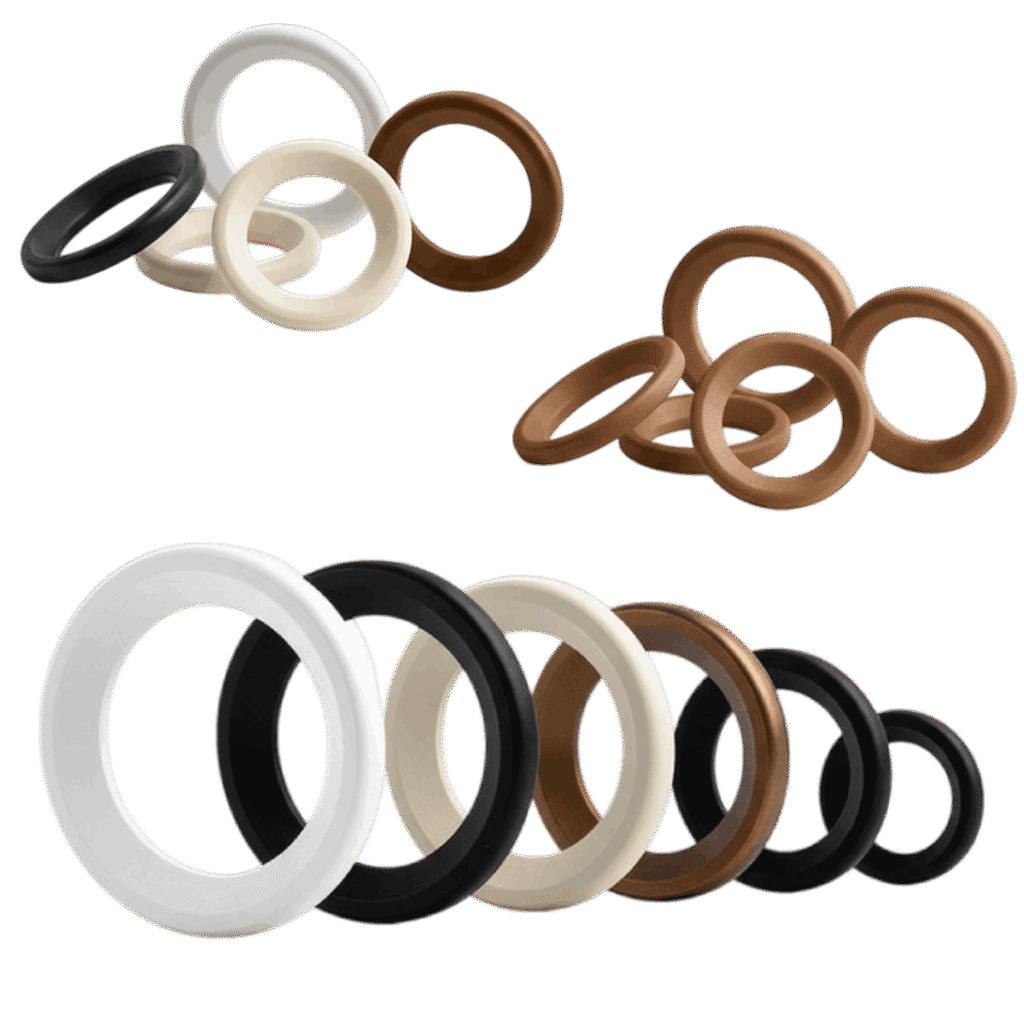

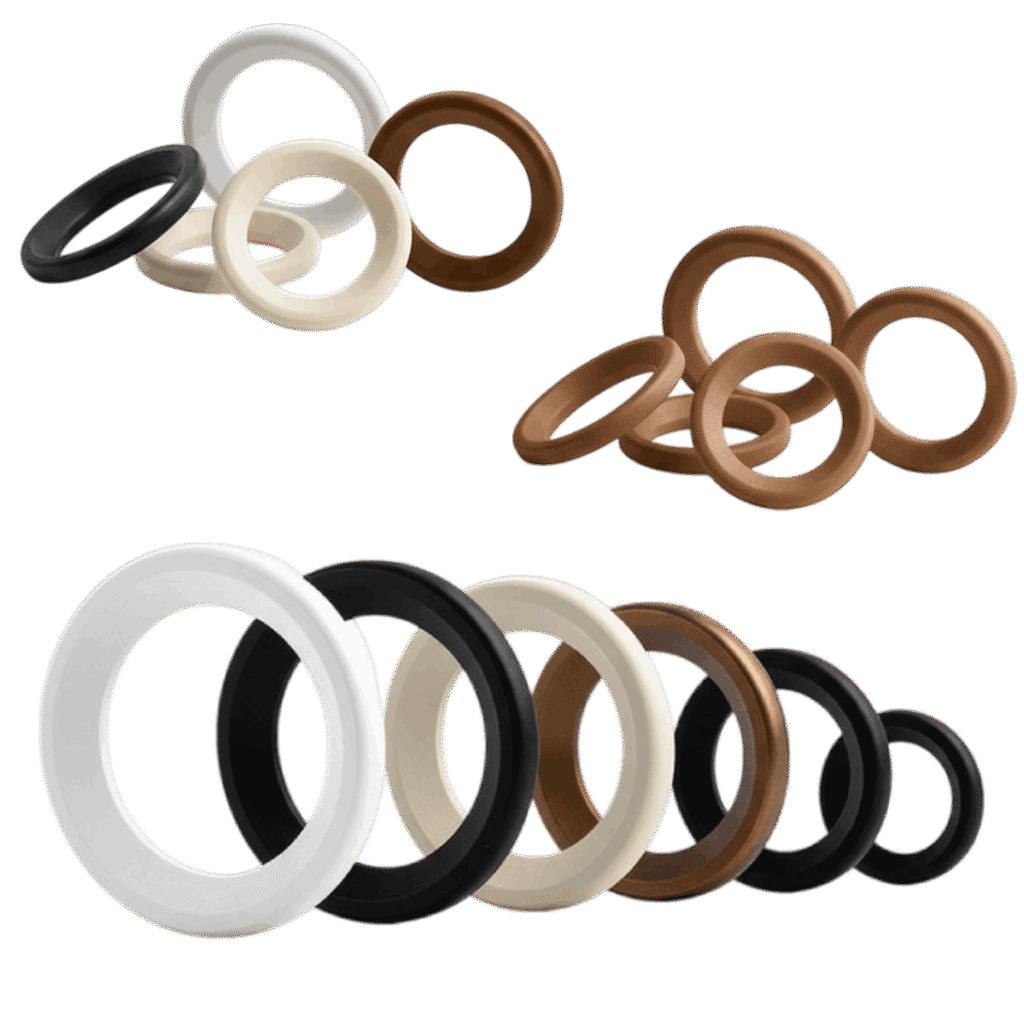

Specialized PTFE gasket products

PTFE grades for a wide range of industrial conditions and applications

You can choose from a wide range of PTFE gaskets to match your operating conditions – from pure PTFE gaskets for maximum chemical resistance, to filled grades such as 25% carbon-filled PTFE, 40% bronze-filled PTFE, 25% glass-filled PTFE, bronze–molybdenum-filled PTFE, and carbon-fibre/molybdenum-filled PTFE for improved pressure, temperature and wear resistance. We also design and manufacture fully customised gaskets based on your drawings and service conditions to ensure reliable sealing performance across your process lines.

Custom PTFE Gasket Manufacturing — Built to Your Specifications

If standard PTFE gaskets do not meet your application requirements, you can order fully customized PTFE gaskets based on your drawings, samples, or precise pipeline dimensions. Material grade, filler type, thickness, diameter, and production volume are all optimized according to your project specifications.

CAD-Based Design and Technical Drawings

Compatible with Your Fluid, Pressure & Temperature

Small-Batch to Large-Scale Production

Optimal PTFE and Filler Grade Selection

Precise Dimensions, Thickness andTolerances

Prototype Sample Manufacturing Available

PTFE Gasket Order Process — From Request to Delivery

From the moment your request is submitted to final delivery, every step of your order is transparent, traceable, and quality-controlled.

Contact Us

Selecting the required PTFE gasket type, contacting us, and submitting your request along with the technical specifications and quantity.

Technical Review and Quotation

Technical evaluation of operating conditions, materials, and dimensions by our engineering team, followed by delivery time estimation and issuance of a pro forma invoice.

Production and Quality Control

Manufacturing the gaskets according to the approved specifications, followed by dimensional and visual quality inspections prior to shipment.

Packaging and delivery

Secure industrial-grade packaging and delivery of the order using the agreed transportation method to your project site or warehouse.

Tosee Teflon — Engineering Industrial Polymers Since 1991

Specialized supply and production of PTFE, Polyamide, Polyurethane, POM, and PEEK for the oil and gas sector and advanced industries.

Tosee Teflon (Ital Orient) began operations in 1991 by importing specialized PTFE, polyamide, polyurethane, POM, and PEEK materials from Italy. Since 1999, the company has established local production lines for PTFE components across various industrial applications.

Its expertise includes process engineering, supply-chain management, continuous quality improvement, technical workforce training, and delivering reliable, long-term polymer solutions for industrial projects.

Contact Us for PTFE Gasket Consultation and Orders

Our technical and sales experts are ready to recommend the most suitable PTFE gasket based on your fluid, pressure, temperature, and operating conditions.

Quality Service and Local Knowledge

Services Areas

- Alabama

- Alaska

- California

- Colorado

- Arizona

- Nevada

Frequently Asked Questions about PTFE Gaskets

If you are unsure which PTFE gasket is suitable for your operating conditions, the following questions can help guide you to the right choice more quickly.

For detailed technical guidance, our engineering team is always available to assist you.

Pure PTFE gaskets offer the highest chemical resistance and are ideal for highly corrosive fluids and aggressive environments. However, they provide lower mechanical strength and wear resistance compared to filled grades.

PTFE grades filled with carbon, bronze, glass, or carbon fiber exhibit enhanced mechanical strength, improved wear resistance, and greater stability under higher pressures and temperatures.

The choice between pure PTFE and filled PTFE depends on the fluid type, operating pressure, temperature, and flange design.

Typically, PTFE gaskets can operate within an approximate temperature range of –20°C to +260°C, depending on the grade and service conditions.

The allowable pressure range also varies based on the PTFE grade, flange design, bolting pattern, and installation quality.

For high-pressure or high-temperature applications, reinforced PTFE grades (carbon-filled, bronze-filled, glass-filled, etc.) are usually recommended.

A detailed technical evaluation is advised before final gasket selection.

Yes. Pure PTFE gaskets are widely used in the food and pharmaceutical industries due to their chemical inertness, non-absorbent surface, and resistance to repeated cleaning and sterilization processes.

In production lines where direct contact with food, beverages, or sensitive pharmaceutical materials occurs, PTFE gaskets are considered a reliable choice.

If compliance with specific regulatory standards is required, an appropriate PTFE grade can be selected accordingly.

Delivery time for standard PTFE gaskets is typically shorter and depends on stock availability.

For custom gaskets, lead time varies based on dimensional complexity, selected grade, and order quantity.

Minimum order quantities also depend on the product type and manufacturing method.

By providing the gasket type and required quantity, we will inform you of the exact delivery schedule and order conditions transparently.

Yes, in many cases it is possible to reproduce a PTFE gasket based on an existing sample. By sending the old or damaged gasket, our technical team will measure and evaluate its dimensions, geometry, and material grade. If necessary, improvements in material selection or thickness can be recommended to achieve better performance.

This method is particularly useful when technical drawings or complete dimensional details are not available.